Non-ferrous sheet metal

Non- ferrous sheet metal: Custom made historic red brass alloy,

Non-ferrous sheet metal

Who is not familiar with this, you want to make an object from non-ferrous metal sheet of a certain alloy, e. g. a helmet of the Urnfield period. But try as you might no sheet metal of the desired alloy can be obtained in the industry. The industry is simply not interested in supplying small and micro-enterprises or cultural science research projects. But that is no longer the case, as the Archaeometallurgy Laboratory has acquired a medium-sized rolling stand, where sheets up to a maximum theoretical size of 500 mm width can be rolled, though in reality a width of 450 mm is more likely to succeed. This is done in a purely hand-crafted process and thus comes close to the requirements of archaeometallurgical research.

The Laboratory for Archaeometallurgy deals with the reconstruction of past production techniques, i. e. the rolling of non-ferrous metals. For about a year now, the laboratory has been working on the production of sheet metal for the production of brass instruments, producing historical sheet metal alloys, casting them into slabs and processing them into sheet metal.

To this end, we have acquired a larger duo rolling stand with which we can manufacture sheet metal in special alloys by hand, which are no longer commercially available. This is of particular interest for the manufacture of instruments as well as for the production of countless archaeological and prehistoric metal sheet finds such as belts, situles, armour, helmets or shields. We are excites about this, because now we are no longer bound to the small selection of bronze sheets that are commercially available and yet already difficult to obtain. For the reconstruction of prehistoric and historic objects we can now produce the sheet metal that is required!.

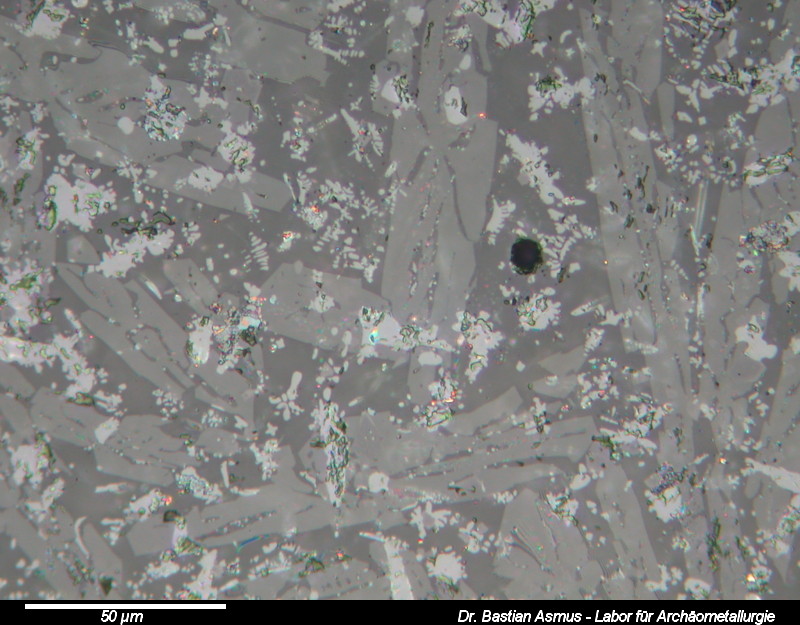

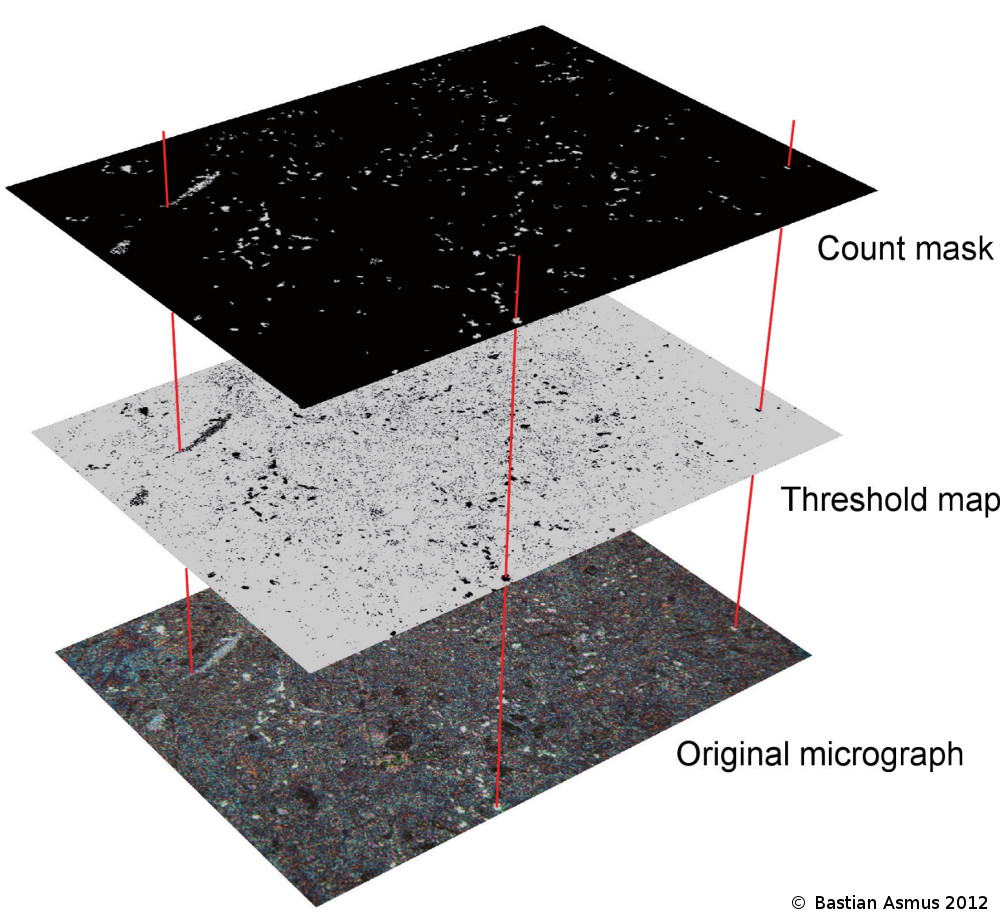

The short film provides a glimpse of the trials and errors that are necessary when making historic non-ferrous sheet metal. By far not every metal alloy behaves in the same manner, some do not like being cast, some do not like being cold rolled. Others yet can only be rolled hot or have to be worked first with a hammer. It is an ongoing enterprise to make historic and prehistoric sheet metal, and a fascinating one, too. Turning a cast object into malleable sheet metal is something that a bronze founder does not do every day. In all cases the slabs and sheet metal to be has to undergo repeated heat treatment in order to produce good quality sheet metal. A process that is monitored by our lab by means of metallography…