Slag analysis – Schlackologie

Slag samples of a medieval (12th century) copper smelting furnace.

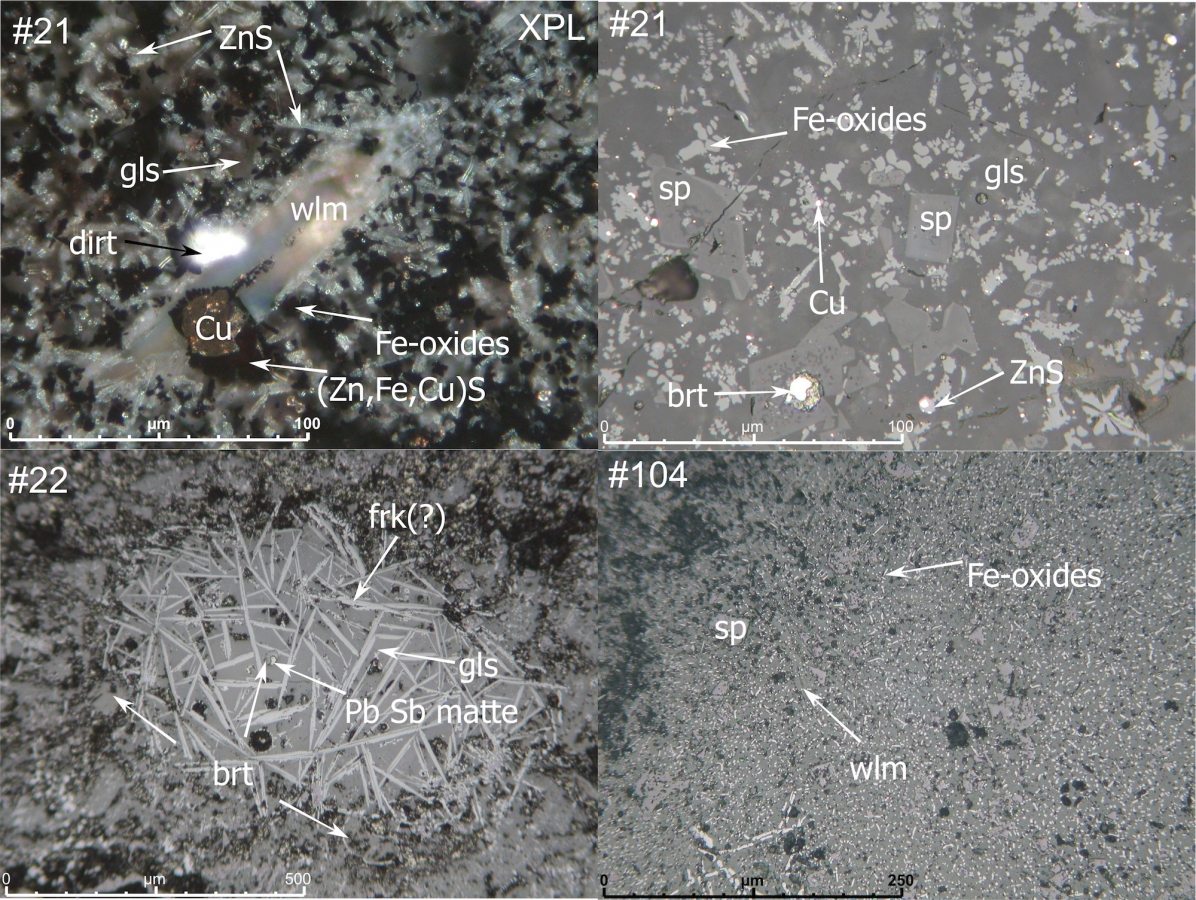

Top left: #21, XPL. Under crossed polarisers the zinc sulphide can be seen as tiny dendrites within the glassy matrix. The other phases are willemite (wlm) and copper (Cu), which is usually asso ciated with the (Zn,Fe,Cu)S phase, an accompanying phase of copper matte at the Huneberg, from which it probably segregates upon solidification. Free iron oxides are seen as dark and much larger dendrites.

Top right: Another section of #21, under plain polarised light. It shows the abundant spinels, the iron oxides and copper inclusions. Most notably it shows the free baryte (brt) inclusion in the slag matrix.

Bottom left: #22, shows more free baryte (brt), together with a lead antimony matte. The long needles are a mixed iron and zinc oxides and are believed to be franklinite (frk?). #104, is rather more affected by corrosion than the other two samples. It shows mainly spinel (sp), free iron oxides and some willemite (wlm). Spinels are in the same order of magnitude than in the other samples.

The colloquial term Schlackologie is used by several German colleagues in the archaeometric sciences when it comes to the analysis and interpretation of mostly metallurgical slags. Literally it would translate to slagology. But why are slags investigated at all and what exactly is slag?

What are slags and what do they consist of?

Slags are by-products of metallurgical or pyro-technological processes and usually remain at the production site as waste product. For example metallurgical smelting slag is usually composed of five separate components: