how to do slag microscopy – sample mounting

This is part three of the series on slag microscopy. Today is about sample mounting: we use a cold mounting procedure, i.e. samples are mounted in resin. I have talked about the find documentation process and the cutting of the sample in parts one and two.

The following things are needed for this:

- cold mounting resin and curing agent

- mixing cup

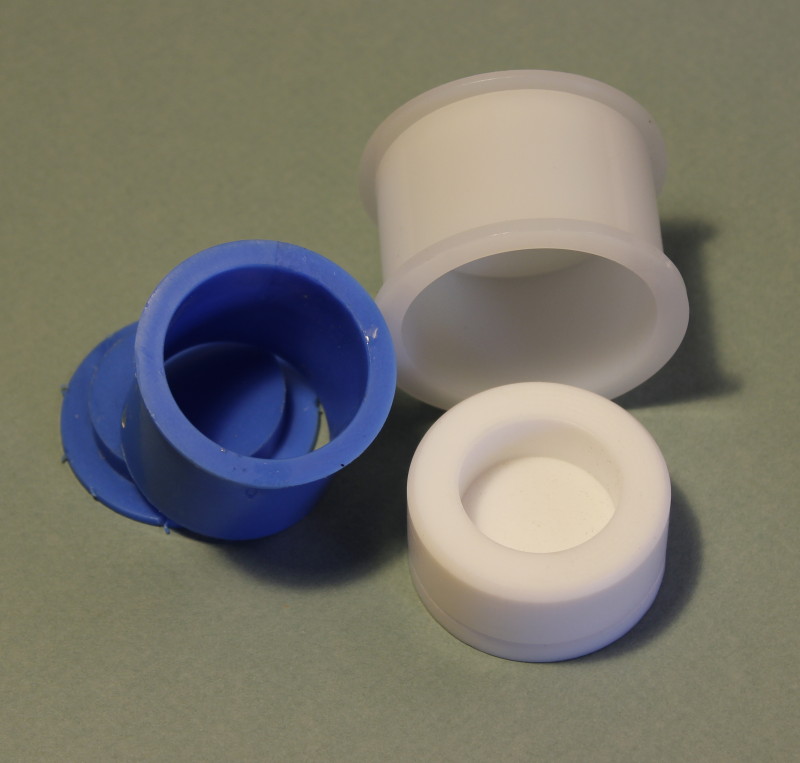

- sample cups

- ultrasonic bath

- IMS

- optional: exsiccator and vacuum pump

- safety goggles

- lab coat or an apron

Sample mounting

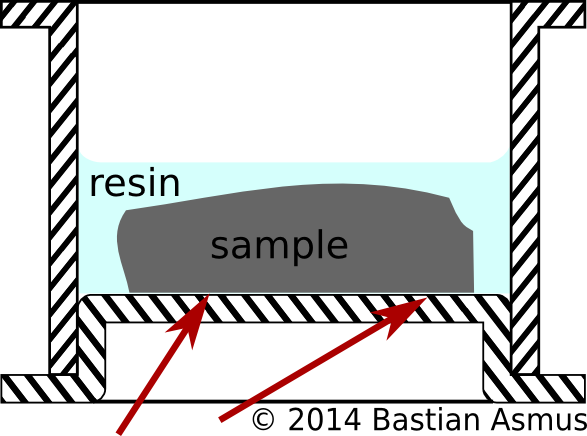

Sample mounting: Cross section sample cup. Make sure that the side facing downwards is flat already. If need be grind this face until it is flat; this will save a lot of grinding time later.

In this series we are using a cold mounting procedure, i.e. samples are mounted in resin consisting of two components: the resin and the curing agent/hardener. Cold mounting is preferable to hot mounting, because low viscous resins may be used to impregnate porous materials. Hot mounting is very useful for less delicate materials like metals, but is rarely used in archaeometallurgy, because it puts quite a lot of mechanical and thermal stress on the samples. Both are things we do want to avoid. As for the mounting resins I am not going further into details about the pros and cons of polyester, metacrylate and epoxy resins at this stage. Suffice it to say that for the normal and everyday use, any of the above mentioned materials will do a good enough job.

Labelling the samples

Because the samples has to identified at a later stage it needs some form of ID label. The ID can be put on piece of paper which is invested alongside the sample, or you can engrave a sample no into the cured plastic block.

There are round labels which are placed into sample cups above the sample in the mounting process. They are not very useful, because they will be at the bottom of our sample once it is finished. You can only read them when you take the from the sample cabinet and turn them over. Sample identification is much more sensible on the side of a sample. When placing the label into the sample cup remember to turn it upside down…

To evacuate or not to evacuate

There are a lot of ingenious devices around that allow you pour the resin into the sample cup under vacuum. These are not necessary for the most parts. It is enough to mix resin and hardener thoroughly and pour this into your sample cup. Even better, do not pour the resin but use a syringe or a pipette. Volumetric pipettes with disposable tips do an excellent job and minimise the development of gas bubbles at this stage. You may then use a toothpick or another sharp implement to remove gas bubbles from resin surrounding your sample.

If you have access to an exsiccator you can use to evacuate the sample. A lot of air bubbles will come to the surface that were previously trapped in the sample within the first few minutes. The whole resin may bubble up quite strongly. Keep an eye on the sample cups during evacuation, or you may have clean your exsiccator. Also avoid the temptation to let the resin cure under vacuum! Why? Resin dissolves gas during mixing, handling and so forth. If you cure the samples under vacuum, this gas may slowly exsolve, and because of the advanced stages of curing may leave trapped as bubbles trapped in your samples. It is far better to evacuate the sample a couple of times and use the ambient air pressure to let the gas bubbles pop.

Recap

- place sample into sample cup

- mix resin according manufacturers specification

- pour resin into sample cup

- optional: evacuate the sample in an exsiccator

- do NOT leave it evacuated for curing

- after curing remove sample from the sample cup

If you found these instructions helpful I am happy to hear about it. Any comments and criticism are equally welcome…

February 21st, 2014 at 22:01

[…] seven part of the slag microscopy course. After sample prep, with find documentation, cutting, mounting, grinding, lapping and polishing we are now going to have a look at the tool to be used for the […]