Nov

4

2013

Bastian Asmus

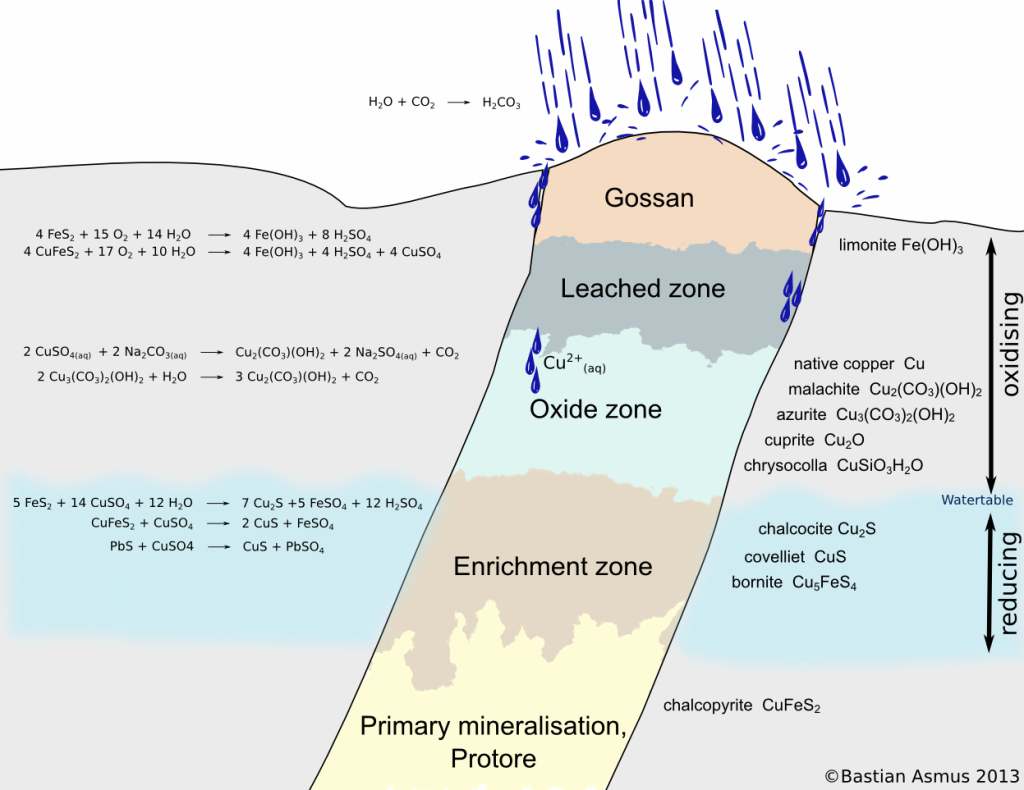

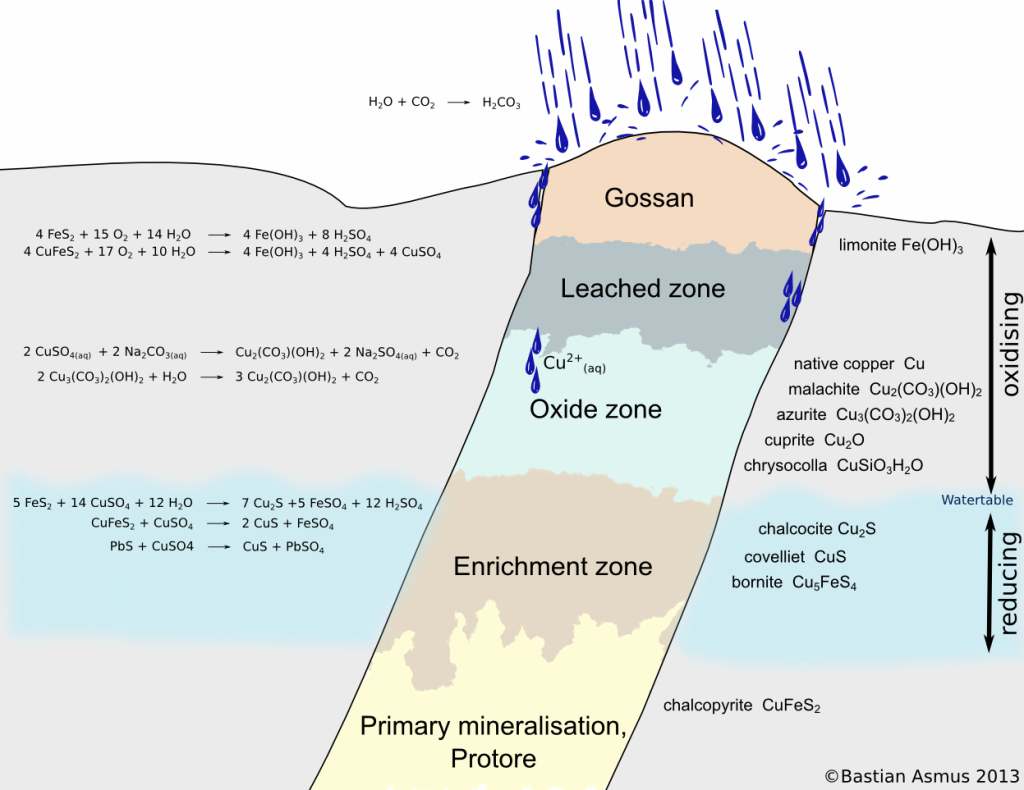

Gossan is a term from mineral economics. The gossan may also be called iron cap. This is so because it denotes a concretion of iron hydroxides that has formed on top of sulphide mineral vein, where it reaches the surface. It forms during the supergene sulphide ore enrichment, when weakly acid surface water perloctaes through the mineral deposit. Many sulphide ores are oxidised in this process and brought into solution:

![Rendered by QuickLaTeX.com \[ H_2 O + CO_2 & \pfeil H_2 CO_3 \]](https://en.archaeometallurgie.de/wp-content/ql-cache/quicklatex.com-686388221fee7b79bb64d22583e4c751_l3.png)

Schematic view of a sulphide vein. You can see the oxidation zone, consisting of the gossan, the leached zone and the oxidised zone. The reducing zone consists of the enrichment zone and the area of primary mineralization. Significantly modified after Evans (1992) and Ottaway (1994).

Continue reading

no comments | posted in Archaeometallurgy, General, Info

Sep

19

2013

Bastian Asmus

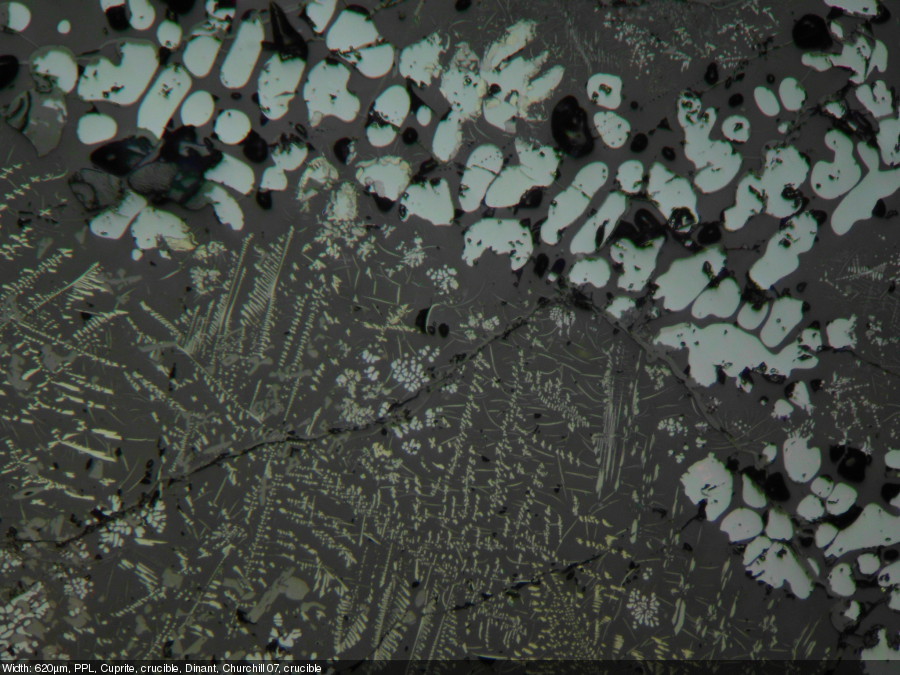

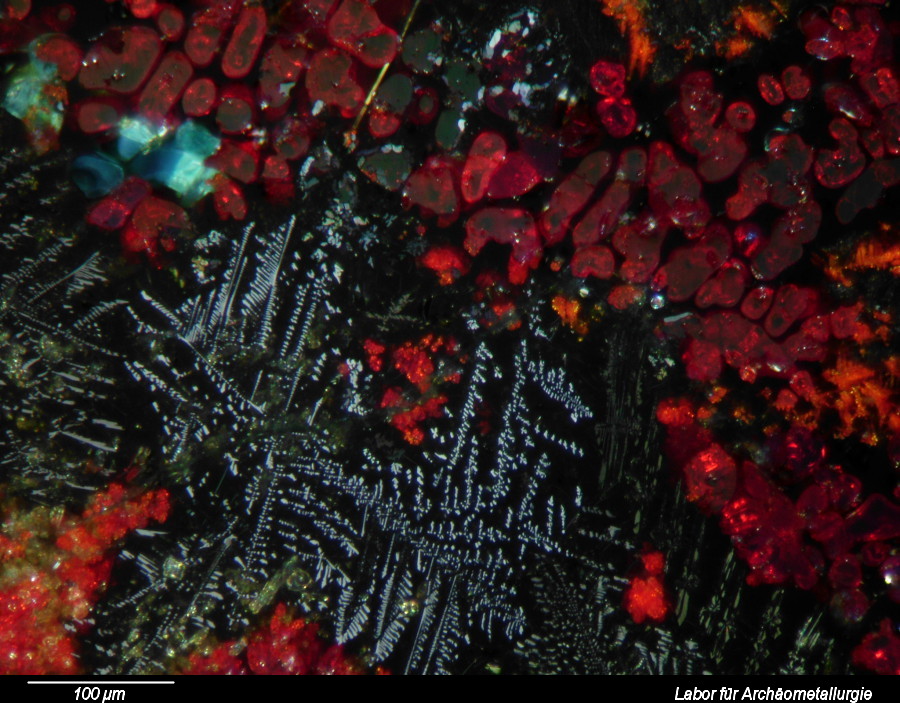

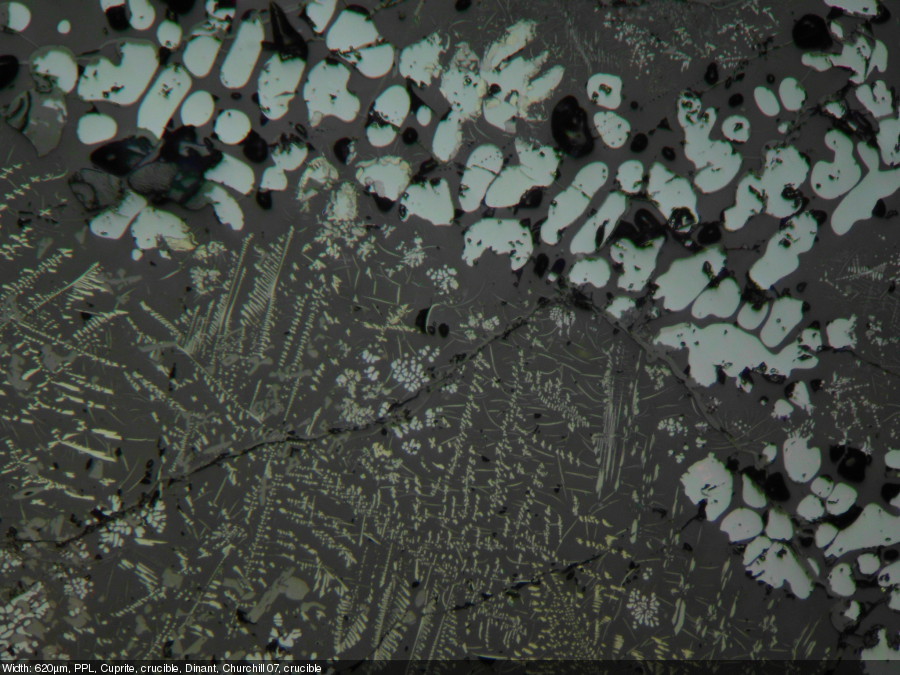

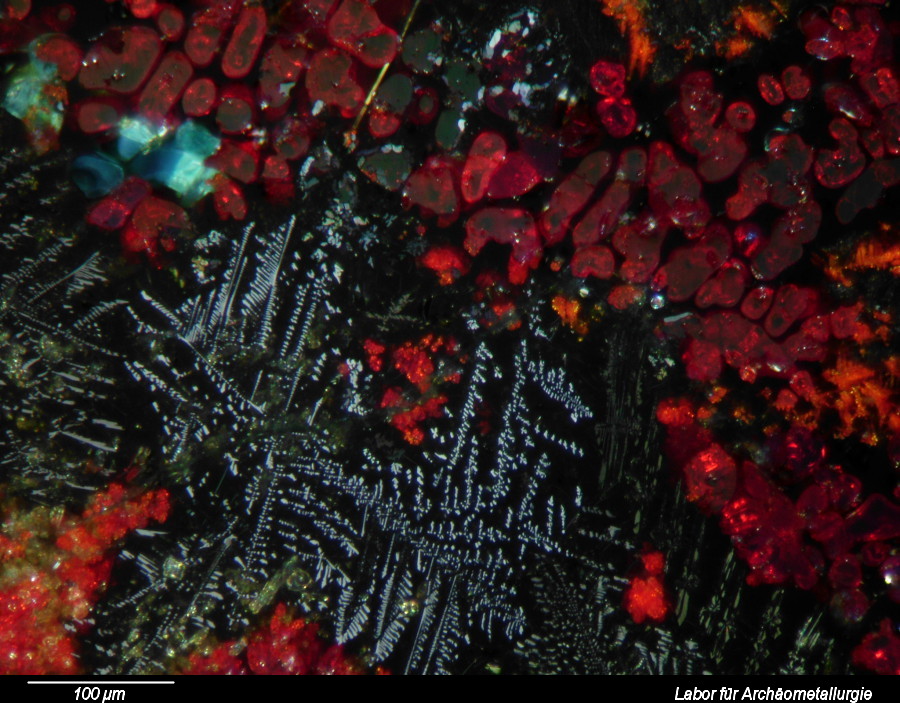

This post describes three of the many possible ways of annotating micrographs with a scale bar: manually, semi-manually and fully automated. Any meaningful micrograph needs a scale as a means of informing us about the size of the documented microscopic structutres. There are two ways possible: Either use the caption to tell us the image width, or annotate the image with a scale bar. The left image (click!) informs us about the image in an unobtrusive bar at the bottom of the image, the right image shows the solution with the scale bar.

1. Annotating micrographs manually

2. Making scale bars – Using Scientific Image manipulation software ImageJ

3. Annotating micrographs using meta tags and a simple shell script

3 comments | tags: Digital Asset Management, How to, microscopy | posted in Archaeometallurgy, Micrograph

Jun

30

2013

Bastian Asmus

[tab: Description]

Bastian Asmus 2012:

Medieval Copper Smelting in the Harz Mountains, Germany (= Montanregion Harz, Bd 10 [Hg. Christoph Bartels, Karl Heinrich Kaufhold und Rainer Slotta]), Bochum (Veröffentlichungen aus dem Deutschen Bergbau-Museum Bochum Nr 191), 2012, ISBN 13: 978-3-937203-63-8

395 pages, english, colour, Appendix for microscopic identification (reflected polarising lihjt microscopy) of slag phases, metal phases, ore minerals and their analysis by SEM-EDS, WDX and EPMA-WDS as well as XRF for bulk chemical characterisation.

44,- Euro

Medieval copper from the Harz

The work deals with the evaluation of a high medieval smelting site in the Harz, near the UNESCO World Heritage sites Rammelsberg and Goslar. With more than 1000 m2 excavated it is to date the most extensive archaeometallurgical investigation of a smelting site in medieval central Europe. It is a site where the polymetallic Rammelsberg ore was smelted to produce copper, lead and silver. The site can be considered as a typical example of a high medieval smelting site in the Harz. Particular emphasis was placed on an interdisciplinary approach which drew upon historical, archaeological and material scientific sources.

[tab: abstract]

Abstract

The Rammelsberg deposit in the Harz mountains in Germany is among the largest metal deposits in the world and has been in continuous use for more than a millennium. There is much controversy as to the nature of the metals produced and the processes involved from the ores of this deposit. This thesis deals with the largest and most accurately excavated smelting site of the high medieval period in the Harz mountains called Huneberg and may be regarded as typical for region and period.

Traditionally historians connect the Rammelsberg with silver production, the mining historians, however point out that the deposit is too poor in silver and that copper was produced in the high medieval period. Modern economical literature classifies the Ram- melsberg as a lead-zinc deposit.

To contribute towards the understanding of these questions an archaeometric study of archaeometallurgic waste- and byproducts, such as slag, furnace lining, furnace wall, litharge and spilled metal drops was undertaken. It builds the base of the interpretation of the metallurgical activities that have taken place at the Huneberg and is contrasted with previous studies. It is suggested that copper, lead and silver in form of argentiferous lead were produced on site, using a complex multi-step process, taking full advantage of the numerous structural features of the site, e.g. the three furnaces present on the site. Successive smelting episodes produced black copper of increasing purity as well as a rather rich argentiferous lead. Because the site is similar to may other sites it is further suggested the mode of metal production at the Huneberg followed a more or less stringent set of recipes and traditions. The mass of 1600 kg slag recovered from the site suggest a copper production of some 600 kg or less, depending on the ore quality. Lead is thought to have been produced in similar quantities, which in turn would mean that the site produced also 1.4 kg of silver during its operation.

[tab: Order info]

Order

44,- Euro plus P&P

Online shop of the German Mining Museum

[tab:END]

no comments | posted in Archaeometallurgy, Science

![]()