Jan

17

2014

Bastian Asmus

This is part three of the series on slag microscopy. Today is about sample mounting: we use a cold mounting procedure, i.e. samples are mounted in resin. I have talked about the find documentation process and the cutting of the sample in parts one and two.

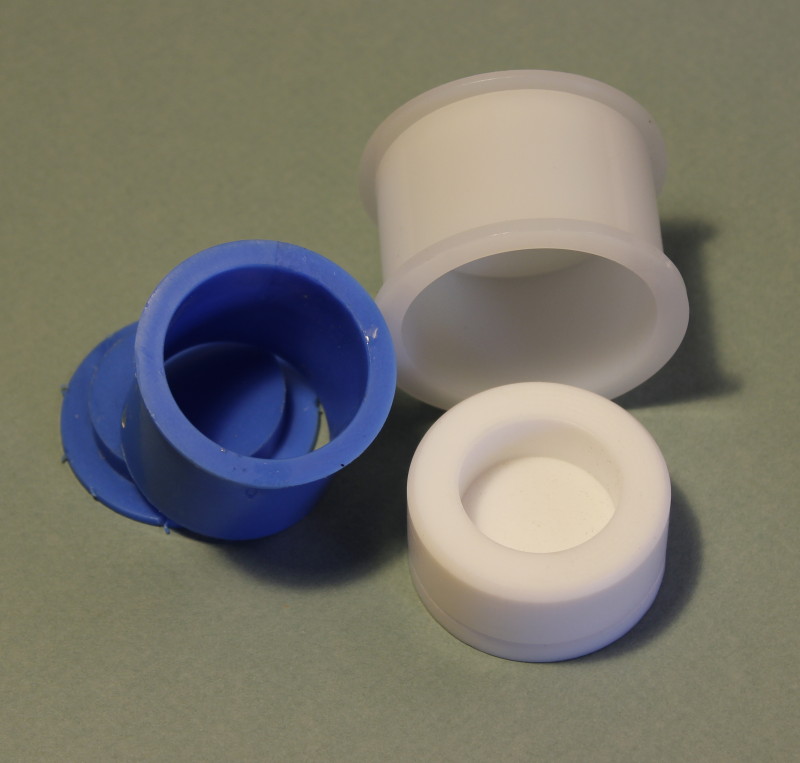

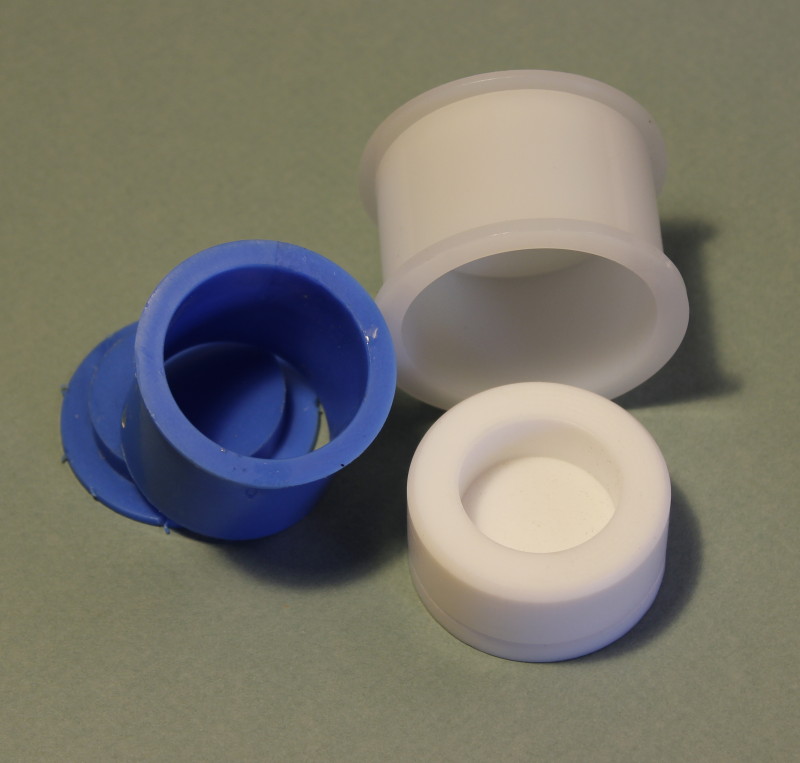

Sample mounting: Three different sizes of sample cups: 20, 32 and 40 mm.

The following things are needed for this:

- cold mounting resin and curing agent

- mixing cup

- sample cups

- ultrasonic bath

- IMS

- optional: exsiccator and vacuum pump

- safety goggles

- lab coat or an apron Continue reading

1 comment | tags: How to | posted in Archaeometallurgy, General, Info, Lab work, Microscopy, slag

Jan

17

2014

Bastian Asmus

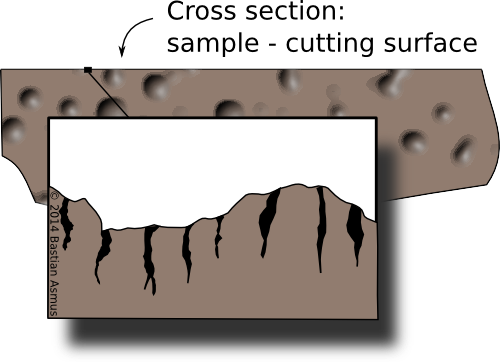

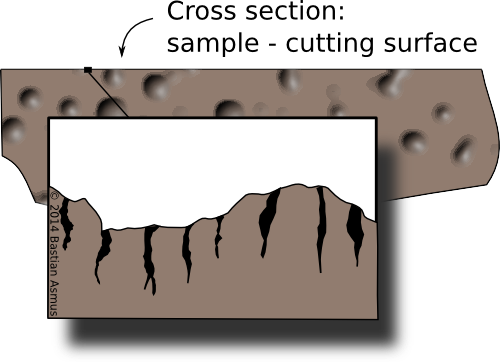

This shows a cross section through a sample. On a micro-scale the cutting surface of a samples is shattered by the cutting process. This areas needs to be removed for samples to be representative of the find.

This is part two of the series on slag microscopy and will deal with sample cutting. Part one was on the macroscopic description and documentation of the sample. Of course these steps may equally employed to mount samples other than slag.

The following things are needed for this:

- a circular diamond blade cutter / tile cutter

- ultrasonic bath

- IMS

- safety goggles

- ear protection

- lab coat or an apron Continue reading

2 comments | tags: How to | posted in Archaeometallurgy, General, Lab work, Microscopy, slag

Dec

18

2013

Bastian Asmus

Another superlative from in Pločnik in Serbia: This time the team of the Rise of Metallurgy project has found evidence for the earliest known tin-bronze. The recovered artefact, a thin sheet bronze fragment, is at least 6500 years old and consists of a copper-tin alloy with 11 wt% tin, and a number of minor elements . Archaeologists call copper alloys with zinc brass, all others are often labelled as bronze. In order to clarify that it is bronze in the sense of the modern definition, in archaeological texts it is often referred to as tin-bronze. Alloys with arsenic are called in the rest of the best arsenical copper. Continue reading

1 comment