Jan

29

2014

Bastian Asmus

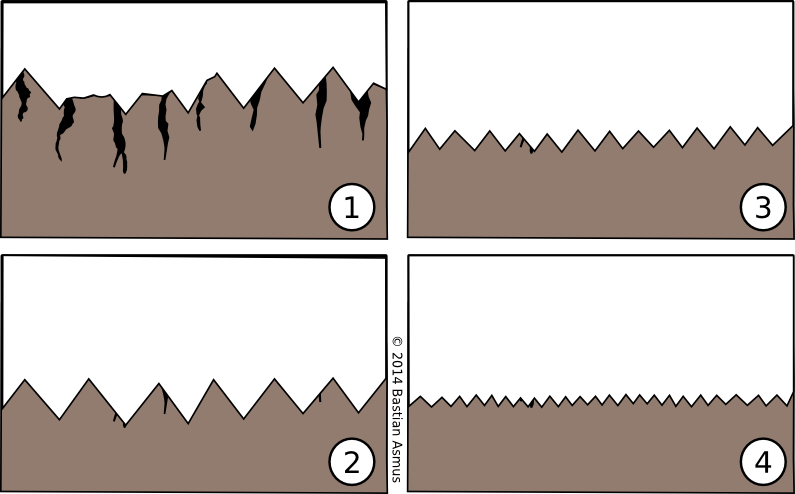

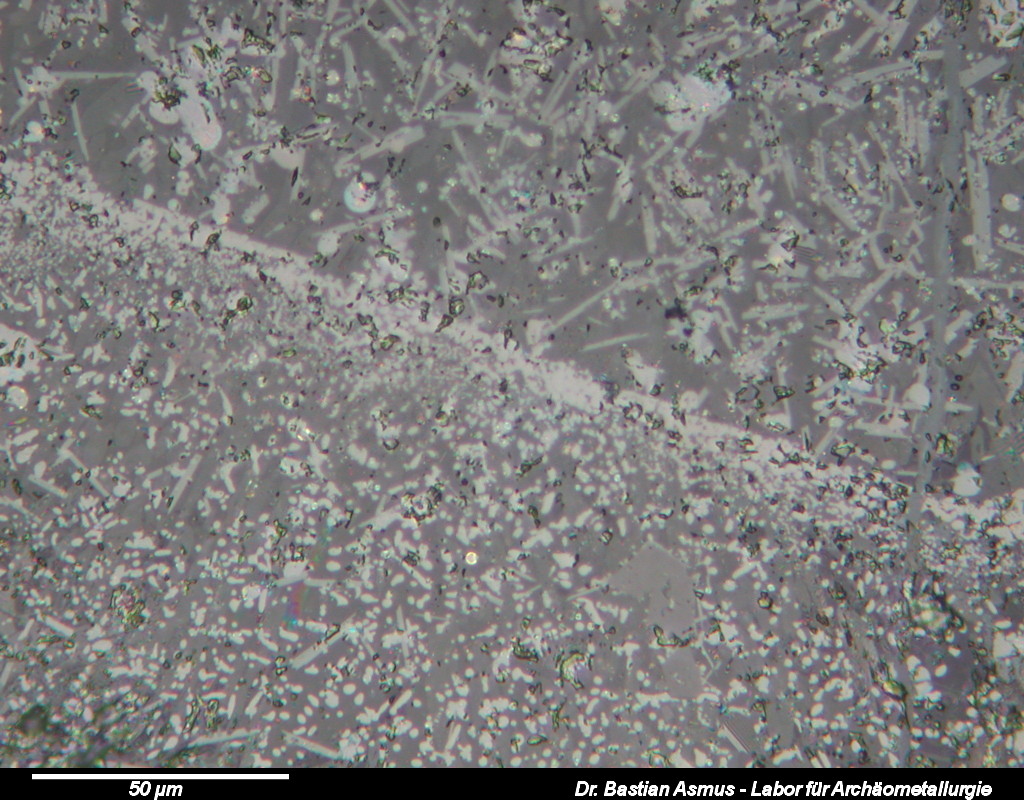

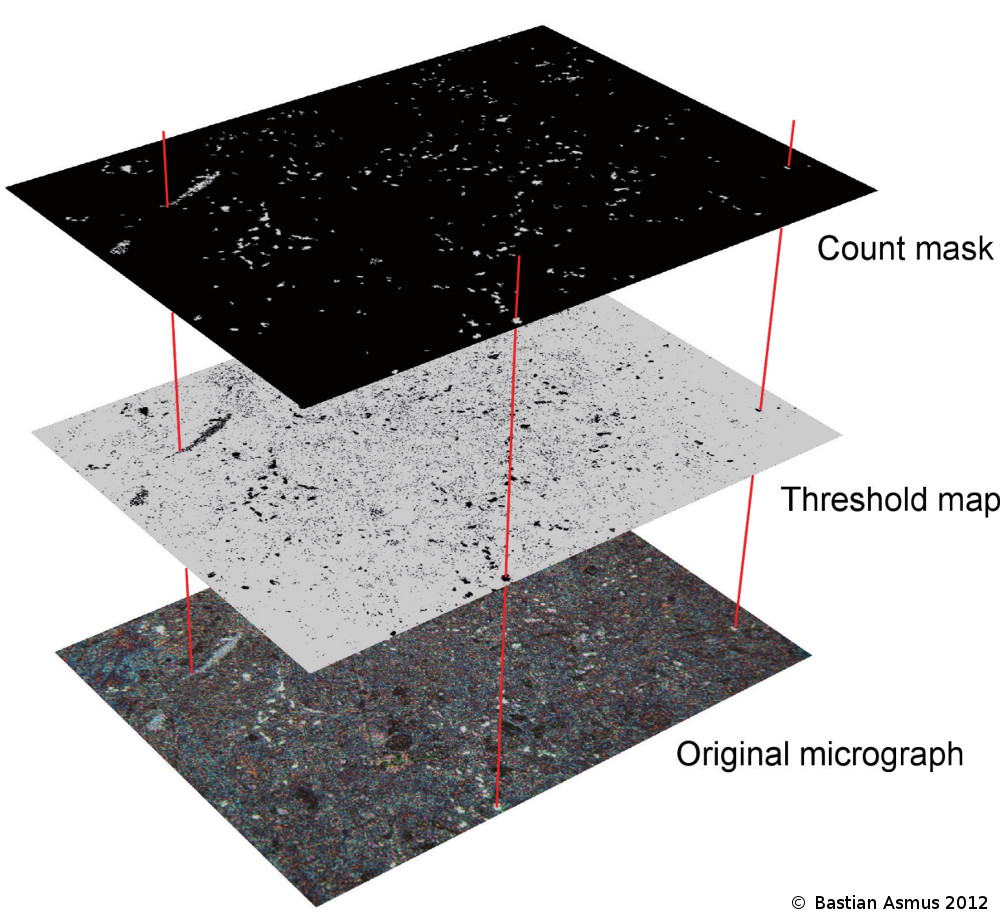

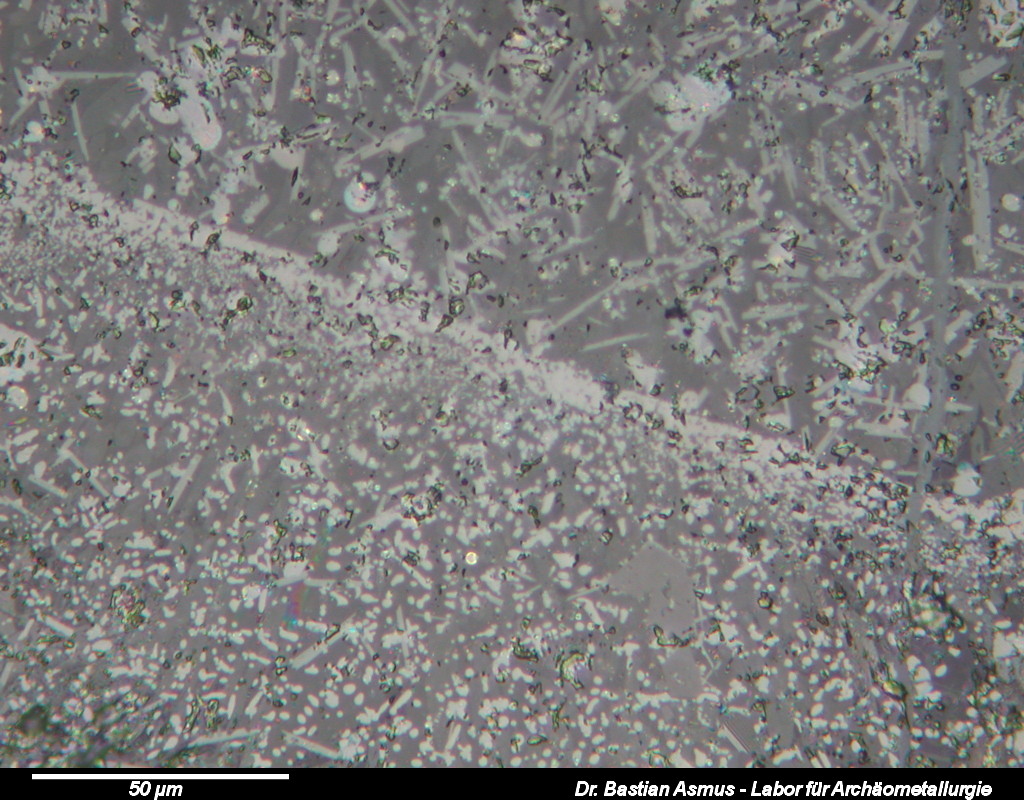

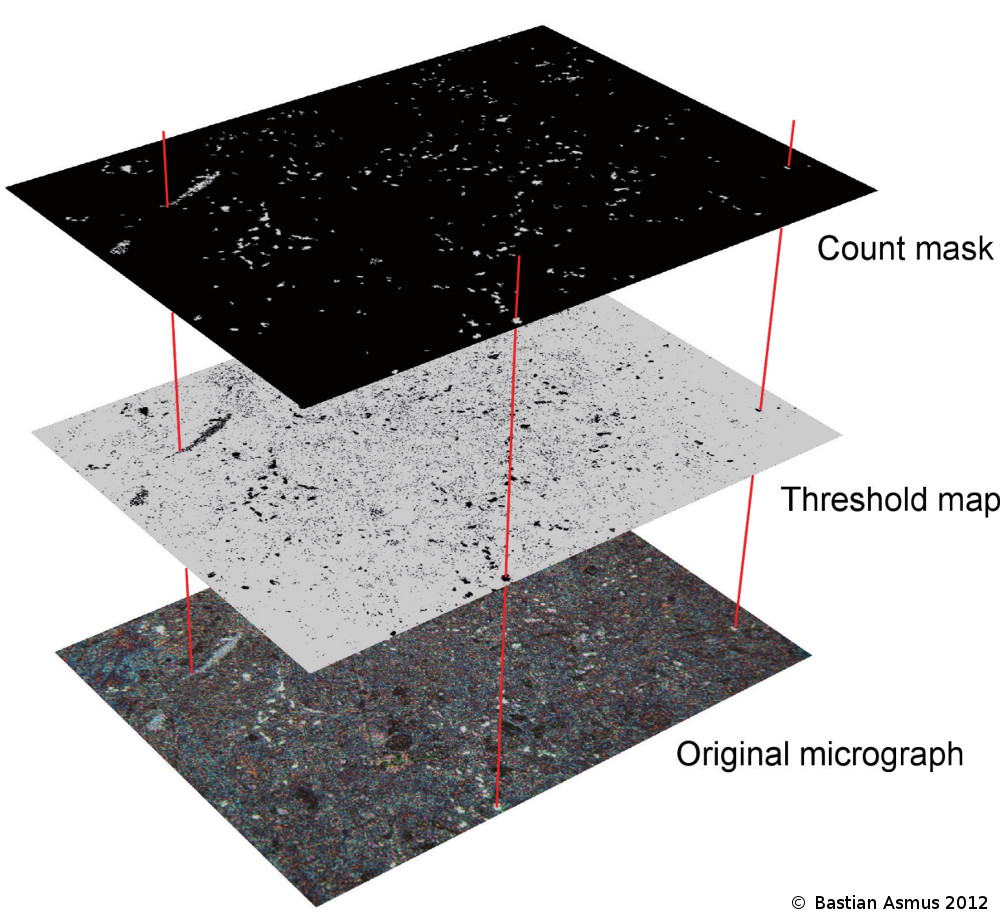

Fig 1: The use of scientific image processing software allows to quantify the area proportion of each phase in optical micrographs. This is a two step process. The original micrograph is converted to a “threshold map” by modifying the colour channels of the source. The resulting black and white image is analysed for their respective area proportions. The count mask is then produced after quantification and may be used to verify which inclusions have been counted.

I used this method during my PhD thesis to approximate the chemical composition based on a micrograph .

I used this method during my PhD thesis to approximate the chemical composition based on a micrograph .

A traditional method for the quantification of an alloying element in another is the estimation of the carbon content of a steel sample. The area of carbon inclusions is estimated by comparison with known standards, or better by measuring them. Area proportions are believed to represent volume proportions and need to be multiplied with the density ρ to calculate wt% proportions. Continue reading

no comments | tags: How to, photograhpy | posted in Analysis, Archaeometallurgy, General, Micrograph, Microscopy, reflected light microscopy, Science

Jan

22

2014

Bastian Asmus

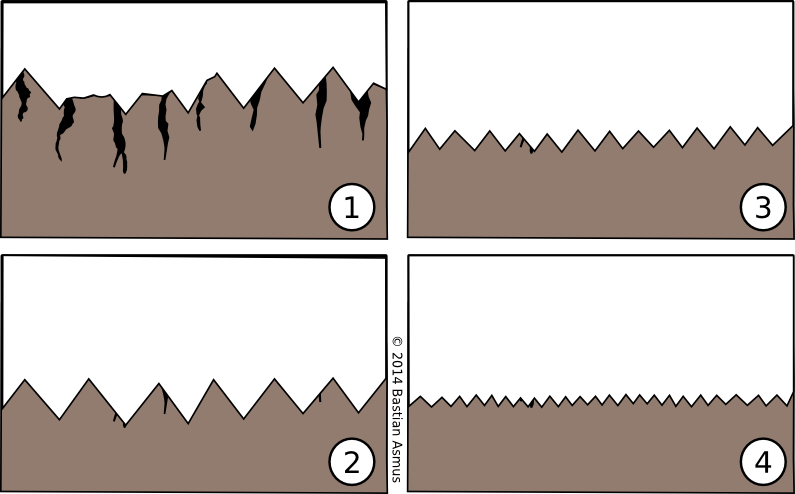

Highly magnified schematic view of a cross section through a sample during the grinding process. Grinding serves two purposes, first to remove micro-shattering caused by cutting (1 and 2), second to prepare the surface for polishing (3 and 4). With consecutive smaller grits you have to remove the scratches left by the previous grit.

Hello to part four of the slag microscopy series. After mounting, it is about time to start sample grinding to prepare the section for polishing.

For this we need:

- a sample polisher/grinder

- abrasive discs

- optional: stereo-microscope to inspect grinding progress

- optional: a marking gauge

Polished section needs to flat. Bottom and top surfaces of the section have to be plane-parallel. A good polish is only achievable if the surface has undergone adequate preparation. This is done by grinding on a horizontal water lubricated abrasive disc. Flatness is usually achieved with abrasives bonded on paper, in synthetic materials or in metal. Continue reading

1 comment | tags: How to | posted in Archaeometallurgy, Lab work, Microscopy, reflected light microscopy, slag

Jan

15

2014

Bastian Asmus

Image 1: The series on slag microscopy you will tell you about how to prepare, describe and interpret polished sections of slag samples. After that you to get hold of a microscope and invest time…

This is the first article of a series on slag microscopy. Excuse me, on what?

Yes you did read correctly: I said slag microscopy. –

This will be a series of articles thought as an introduction to the most noble and useful art of slag microscopy, the equipment needed to do slag microscopy and what slag microscopy is all about. Today’s topic is sample preparation! Slag microscopy is a small but fun part of one the most fascinating disciplines of archaeology: archaeometallurgy (: and it is very useful for us archaeometallurgists, too.

Why? Because slag tells us a lot about the processes and products of which slag is a by-product. In order to be able to tell what slag tells us we need to have a look at it through the microscope. We have to prepare a polished section and will describe the microscopical appearance of the sample under the polarising reflected light microscope.

1 comment | tags: How to | posted in Archaeometallurgy, comparative collection, Lab work, Microscopy, Science, slag

I used this method during my PhD thesis to approximate the chemical composition based on a micrograph .